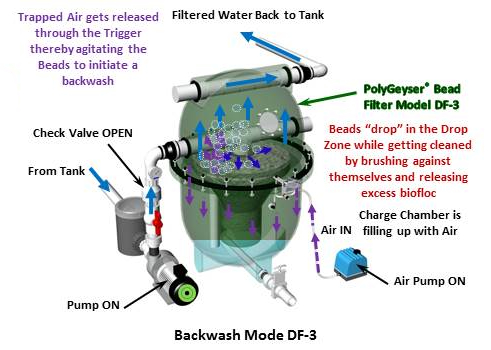

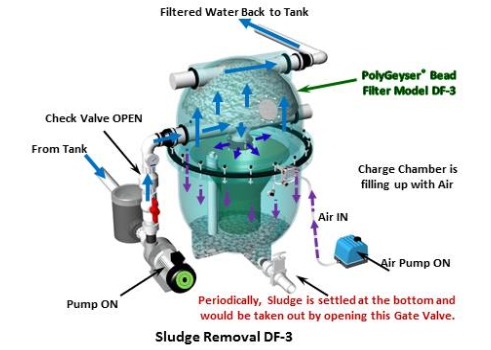

The self-automated backwash process requires no moving parts or electronics.

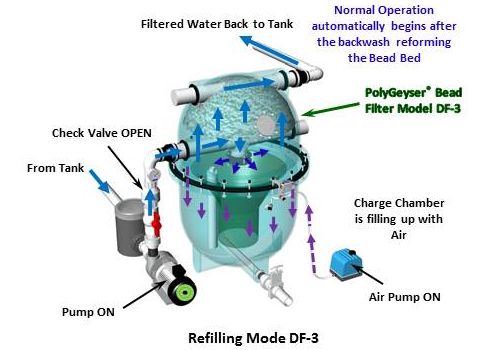

Under development for several years, the patented PolyGeyser® technology is capable of handling ammonia loads 50% – 100% higher than standard bead filters at a fraction of the water loss and head loss.

The innovative backwash process prevents caking and clogging – keeping your day-to-day operations moving along smoothly. The backwash is gentle, keeping the biofilm intact while allowing the system to operate for long periods of time with no maintenance.